Line of business

These are the areas of our business

-

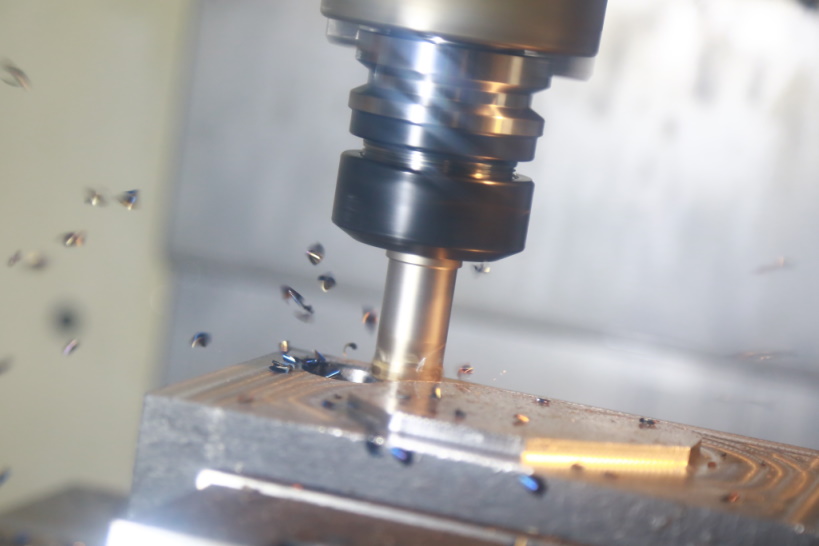

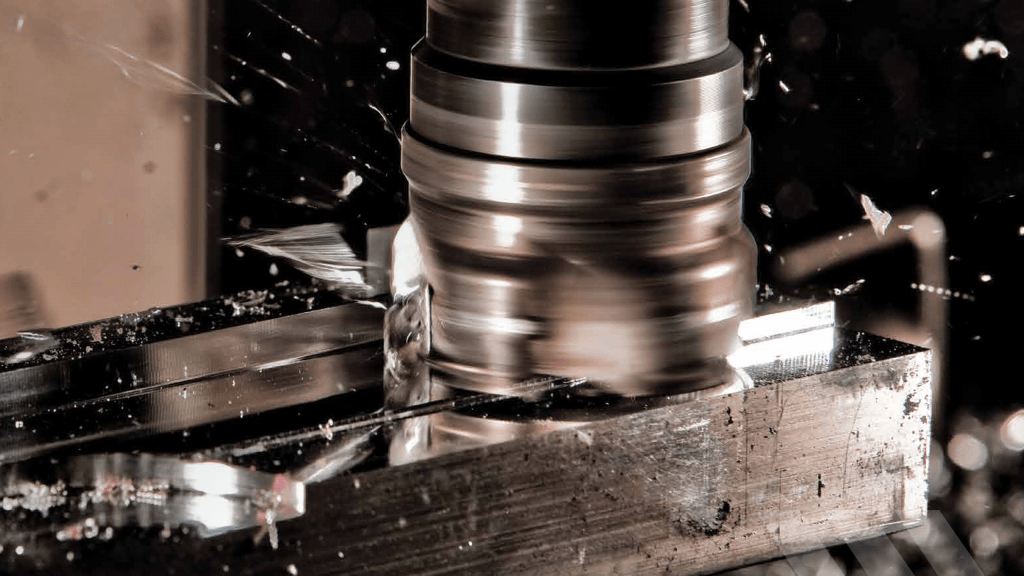

CNC Milling

Exact computer controlled process to create a range of components from 1mm to 400mm cubed

-

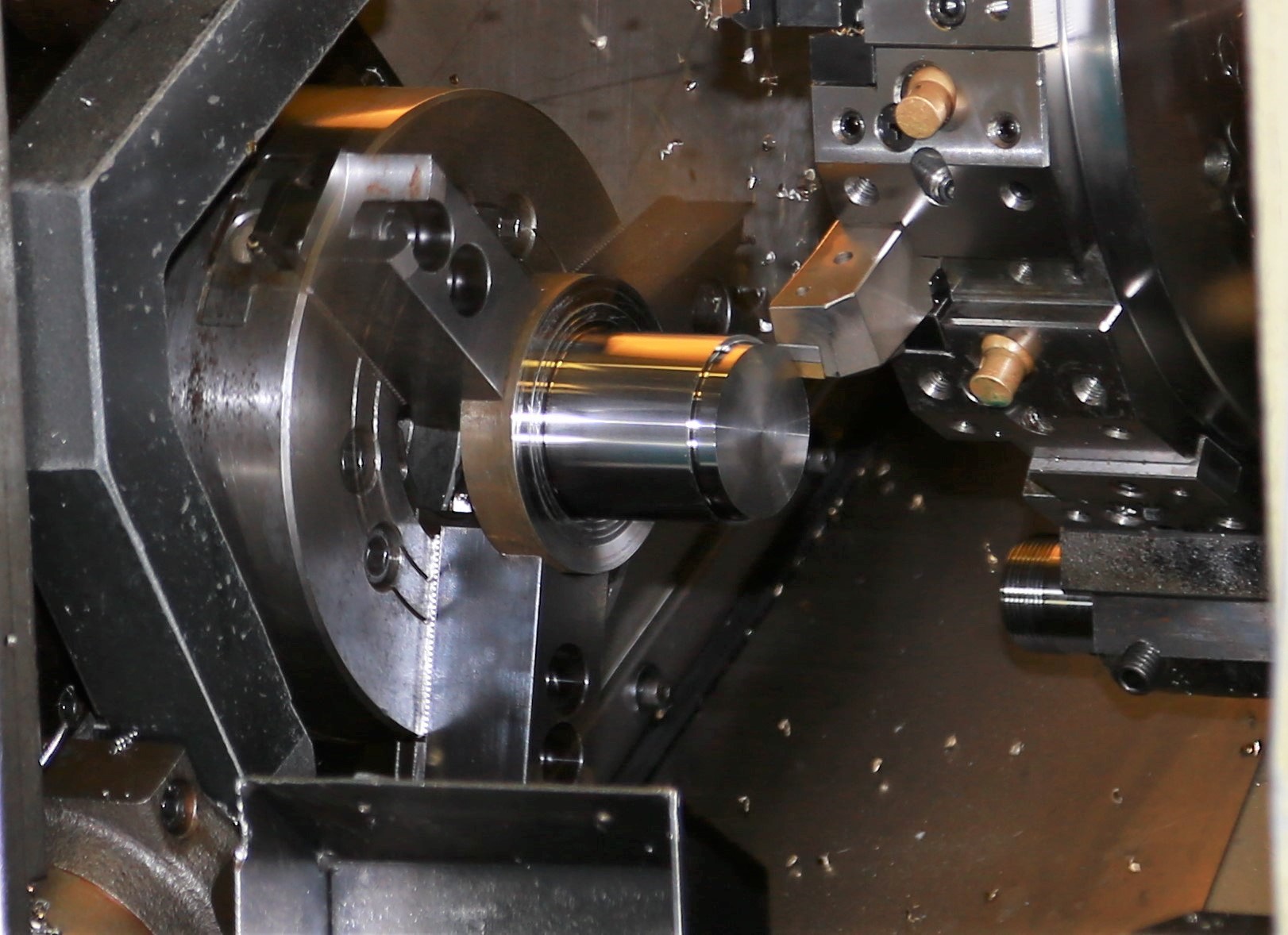

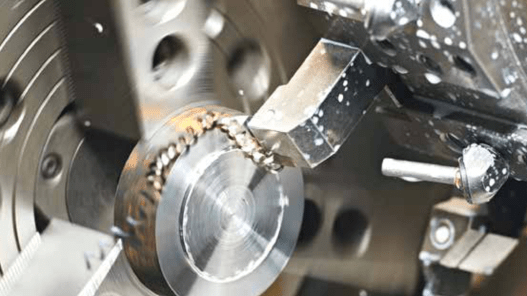

CNC Turning

Expert turning of components ranging from 1mm to 150mm diameter and 0.1mm to 300mm in length.

-

Fast Action Breakdown service

This services runs 7 days a week, so should the unexpected happen we will get you back up and running again quickly.

-

Precision Machined Components

Newold Precision offer additional engineering capabilities, see our services for details.

-

Design Consultancy

We offer besoke design consultany for your projects.

-

Quality & Inspection

We aim to supply our customers with a high quality service.

Why choose us

Newold Precision can offer a wide range of engineering capabilities including CNC Turning, CNC Milling, grinding, welding & brazing, shot peening, spark / wire eroding, finishing, painting, surface and heat treatments, assembly and the design and production of prototype parts.

BEST SERVICES IN THE INDUSTRY

At Newold Precision Engineering we specialise in the production and repair of high quality precision machined components.

We are able to carry out a wide range of CNC machining and repair-work in house, utilising our range of manual and CNC machines.

01. Precision Machined Components

Precision components are machinery parts that are manufactured solely for industrial and machine-based companies working in different sectors and with different aspects of the engineering world. They tend to be used in different applications, such as turning and machining.

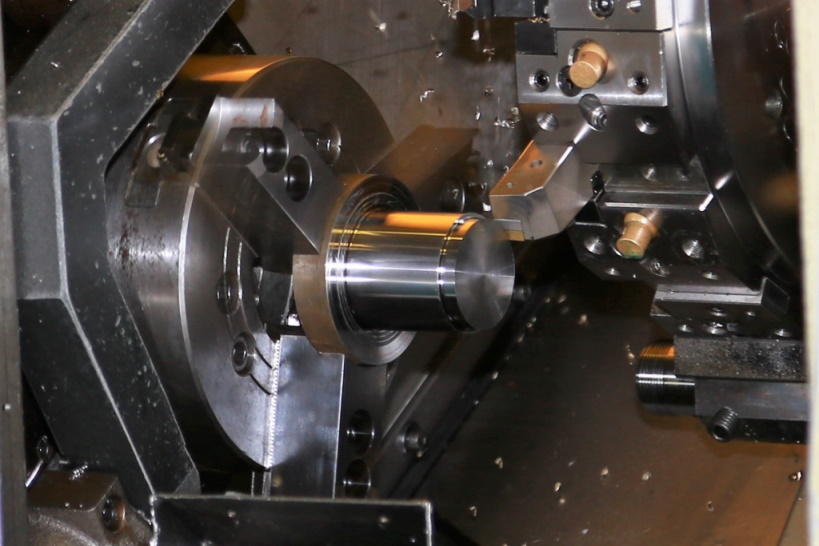

02. CNC Turning

With CNC turning a metal bar is fed into the lathe and rotates at speed while a single-point cutting tool removes portions of the metal to create the desired shape. Component sizes ranging from 1mm to 150mm diameter and 0.1mm to 300mm in length can be produced.

03. CNC Milling

computer numerical control milling

CNC milling, or computer numerical control milling, is a machining process which employs computerized controls and rotating multi-point cutting tools to progressively remove material from the workpiece and produce a custom-designed part or product.

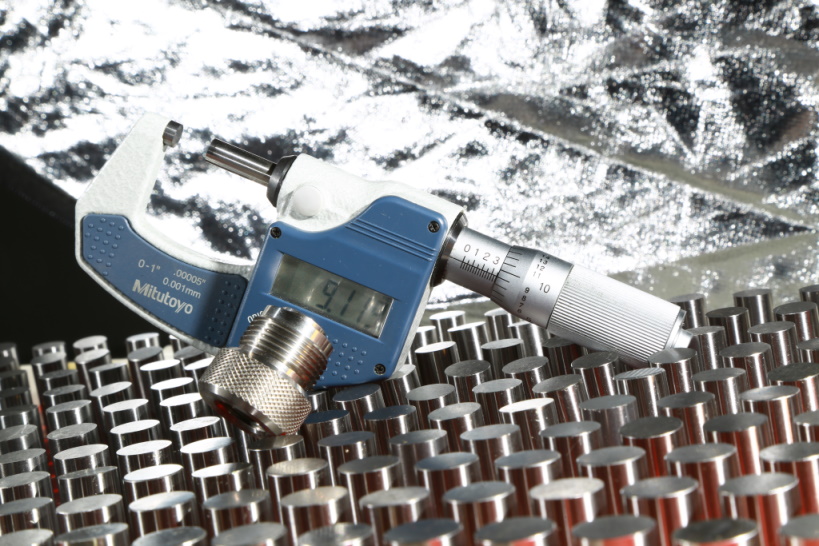

04. Quality & Inspection

The members of Newold Precision Engineering have gained over 30 years experience in the methods of production and repair of precision engineered components, working to ISO 9001 standards, within the aerospace, mining, medical, F1 and pneumatic industries.

Products & Services

At Newold Precision Engineering we specialise in the production and repair of high quality precision machined components.

We are able to carry out a wide range of CNC machining and repair-work in house, utilising our range of manual and CNC machines.

01. Precision Machined Components

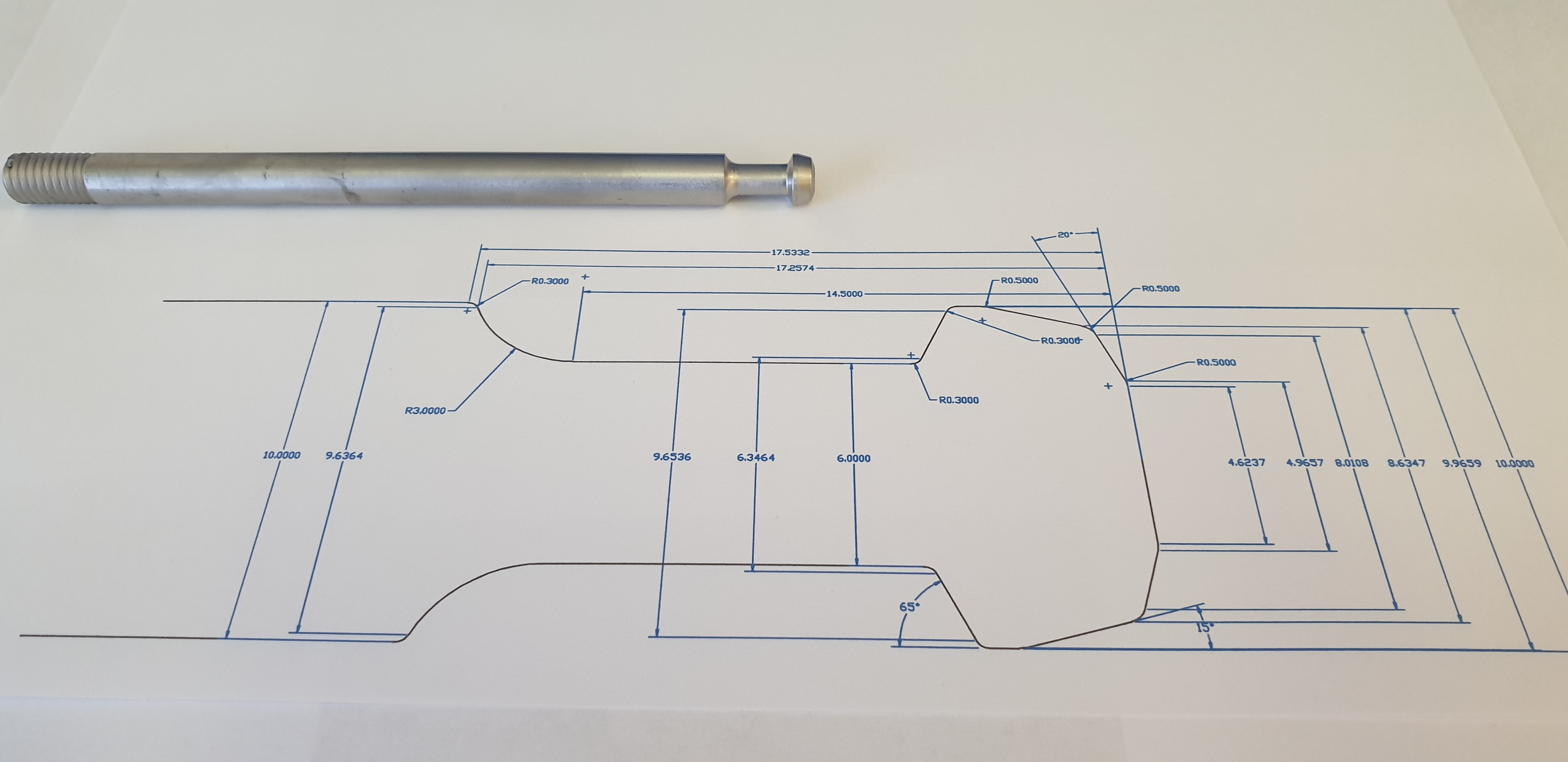

We have gained many years experience in designing and producing new components. We are also experts in the repair and refurbishment of old components. We aim to return the product back to the customers original specifications

02. CNC Turning

We offer high range accuracy precision CNC turning of components in a wide variety of materials. Ranging from soft plastic all the way through to more exotic materials such as Titanium and Inconel. With component sizes ranging from 1mm to 150mm diameter and 0.1mm to 300mm in length.

03. CNC Milling

We offer precise CNC milled components, and a wide range of services to solve even the most demanding engineering problems. Component sizes ranging from 1mm to 400mm cubed.

With the aid of C.A.D (Computer Aided Design) software we are able to tackle even the most complex of products in both turning and milling operations.

04. Quality and Inspection

With an extensive range of inspection equipment and access to a CMM (Co-ordinate Measuring Machine) and Shadowgraph, our aim is to supply our customers with products that meet their expected standard of quality while also being delivered in a timely manner.

Made in England

Made in England